:: Vertical Submerged Process Pump C.I. / M.S. / S.S. / Alloy 20 / Aluminium ::

In many applications in the chemical process filed, the use of vertical pumps for transfer or other services offers many advantages. perfect heavy duty vertical process pump handles clean, oily, sandy, corrosive liquids - the varied applica-tion industries include Chemical & Petrochemicals, Foods & Pharmaceuticals, Sugar & Paper mills, waste water treatment plants etc.

We are specialists in corrosion resistant pumps, now offer a group of vertical pump process pumps especially built for heavy duty service, pumping corrosive liquids. A wide range of sizes for pit depth to 20 ft. in both the wet pit or submerged Steel / Stainless Steel with all parts of the unit in contact with the liquid made of this highly corrosive resistant material. Other materials to meet user's requirements are also available

Outstanding Features

- Pump assembly including cover plate is a complete unit. A series of inter locking love joy couplings provides permanent allignment.

- Upper bearing easily replacable without disturbing pump or piping by removing only themotor and couplings.

- Upper bearing fully protected from pit fumes and atmospheric effects.

- All units furnished with love-joy couplings.

- Due to standardized parts design, unit may be adopted in field for changed pit depths or pump ratings by simply ordering new parts required. Not necessary to purchase a complete new unit.

- Sized for low P V loads for long bearing lift. Special proper support of intermediate shaft is provided.

- Unit length can be changed by changing only shaft and column components.

- Centrifugal, Quiet, Vibration-free.

Submerged System

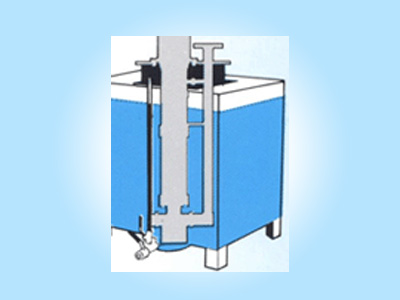

With this type of uints, the single pump is placed directly into the sump or vessel which contains the liquid to be pumped. Suction opening is furnished with a slotted type full area strainer - if required.

Duplex unit

Two Pumping units are mounted on a common pit cover.s

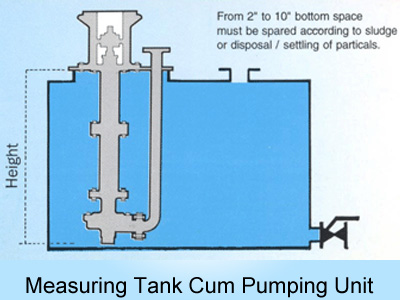

The unit, innovatively developed by "Plasto", is specially designed to transfer exact quantum of liquid. It continuously indicates the level (quantity) of the liquid in the storage tank. With help of overflow level setting. only specific quantity of the liquid can be allowed to be transferred.

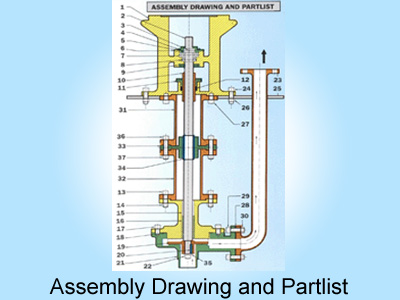

| ASSEMBLY DRAWING AND PARTLIST | ||

|

1. Bearing Housing Frame. |

2. Main Shaft |

3. Bearing Collar Lock Pin |

|

4. Hex Bolt. |

5. Bearing Collar. |

6. bearing Cover. |

|

7. Upper Bearing. |

8. Lower Bearing. |

9. Oil Seal. |

|

10. Rotary Bush. |

11. Gland. |

12. Gland Packing. |

|

13. Hex Bolt. |

14. Hex Nut. |

15. Body Back Cover. |

|

16. Rotary Bush. |

17. Hex Bolt. |

18. Gasket. |

|

19. Impeller. |

20. Impeller Key. |

21. Main Body. |

|

22. Impeller Main Nut. |

23. Outlet Flange. |

24. Hex Bolt. |

|

25. Cover Plate. |

26. Hex Nut. |

27. Hex Bolt. |

|

28. Gasket |

29. Hex Bolt. |

30. Hex Nut. |

|

31. Pipe Column Extension (top) |

32.Pipe Column Extension (Bottom) |

33. Steady Bearing. |

|

35. Plain Washer. |

36. Hex Bolt |

37. Hex Nut. |

Plasto Pumps & Valves. All Rights Reserved. | Designed By : GID - Promoted By : MID |